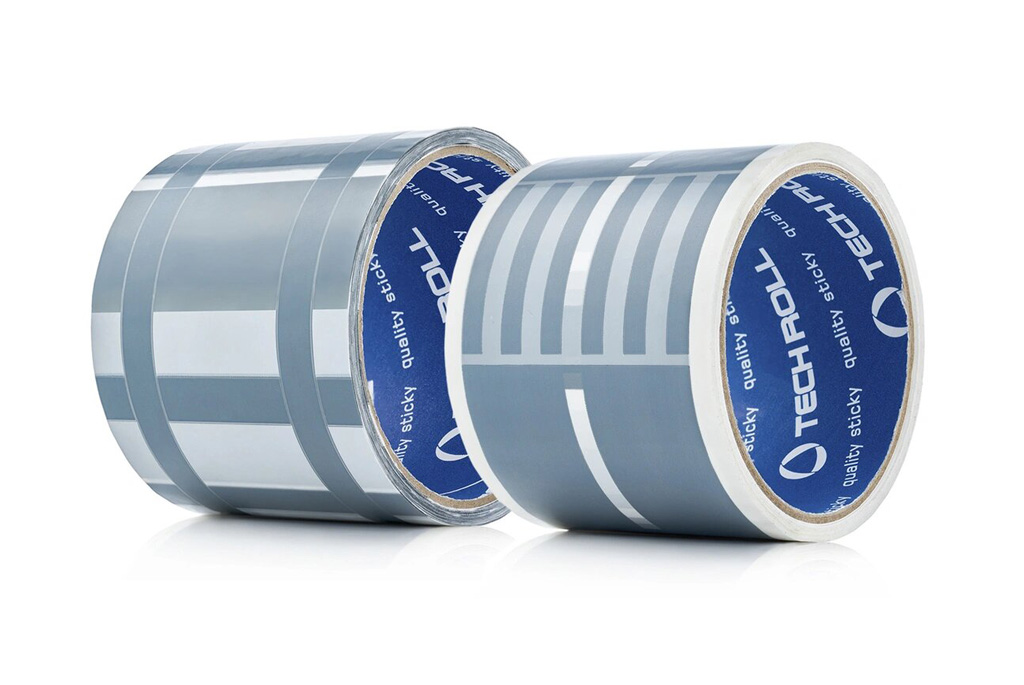

Insulating tape

Insulating tape is a polyvinyl chloride film made of PVC composition by roller-calendering method, with an adhesive layer applied to one side, and cut into strips of a certain width of 15 mm or 19 mm.

Electrical tape is widely used by consumers in everyday life, as well as by professionals when performing various types of work:

- in electrical work: insulation of wires, marking, connection into bundles, insulation of wires at the connection points, installation of lamps, minor repairs of devices (for example, replacement of a plug);

- in plumbing works: sealing and strengthening of joints and seams, waterproofing;

- fixing various items;

- protection of electrical cables and wires from mechanical stress, restoration of the braid in case of damage.

Electrical tape characteristics

Electrical tape is a single-sided adhesive tape.

Main technical characteristics:

- base material: polyvinyl chloride;

- manufacturing method: roller-calender;

- adhesive composition: synthetic rubber;

- width: 15 mm and 19 mm;

- operating temperature: from -30 to +50 degrees Celsius.

The electrical tape has high flexibility and ductility, tensile resistant. Also, insulating tape is highly resistant to fire and chemicals, does not react.

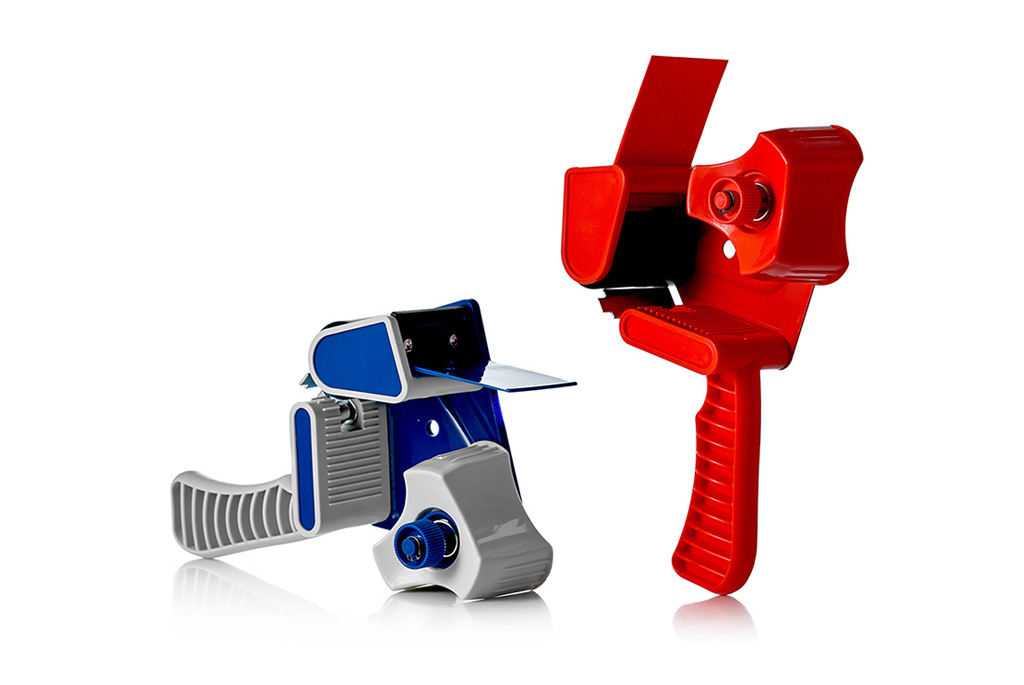

Under the condition of storage and operation in the specified temperature range, the electrical tape retains all its properties for a long time, does not dry out or exfoliate. It is convenient to work with electrical tape, no special tools are required: it is easily detached from the bobbin and cut with ordinary scissors. The adhesive composition of the electrical tape is safe for the skin of the hands during work; additional protection is not required. Insulating tape does not emit harmful and hazardous substances.